More about IoT Solutions

Established in 2015

Download our company profile

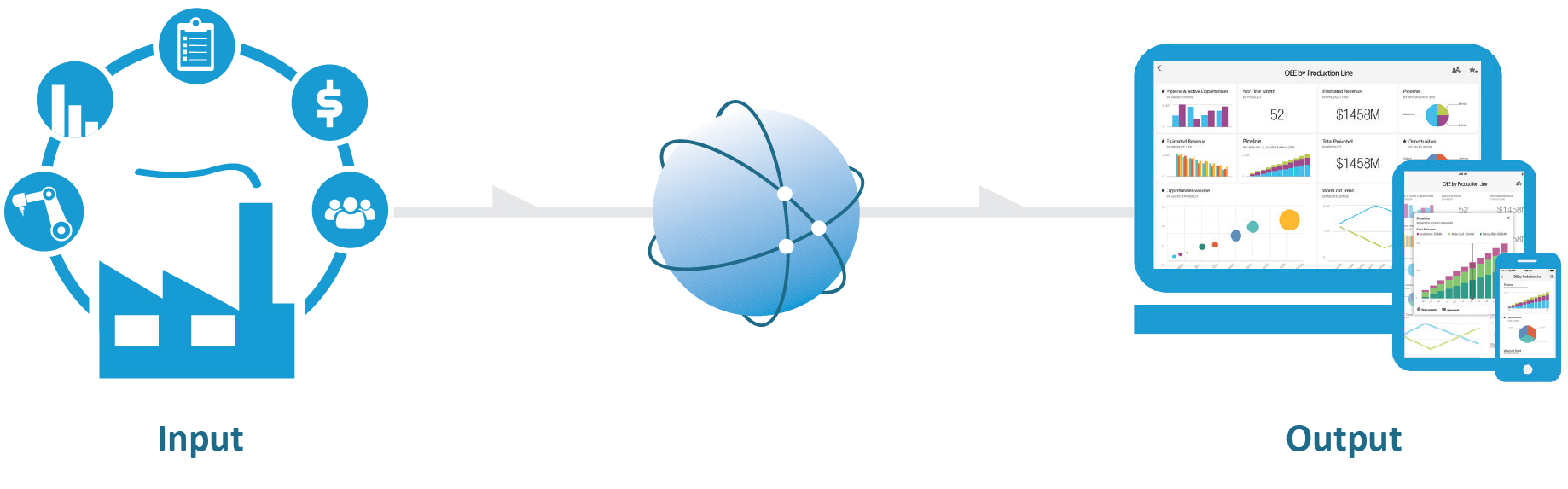

IoT Solutions was created to help companies integrate and automate their manufacturing and maintenance functions. In our experience, implementing practical and effective systems is also used for long-term manufacturing planning. By integrating and automating manufacturing systems, you have full access, transparency and control over your manufacturing environment.

Moreover; accurate and real-time data-from-source is always available to improve efficiency, effectiveness, quality and speed of production processes. By creating a visual management environment in the workplace ensures full visibility and control on the work floor with rapid and accurate responses. We offer a system that improves manufacturing throughput, quality, consistency and cost.

Our Approach to Challenges within Manufacturing Environments

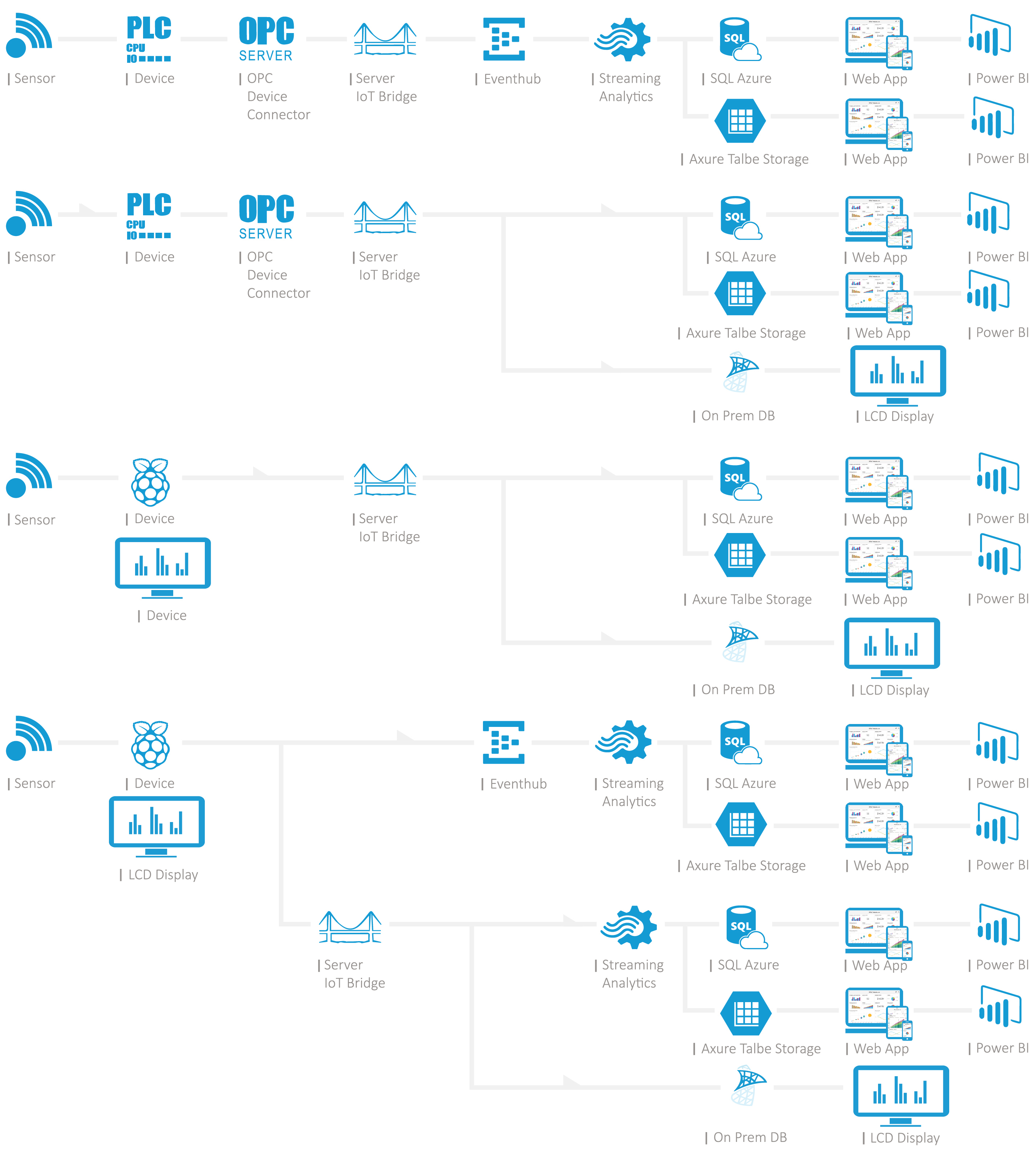

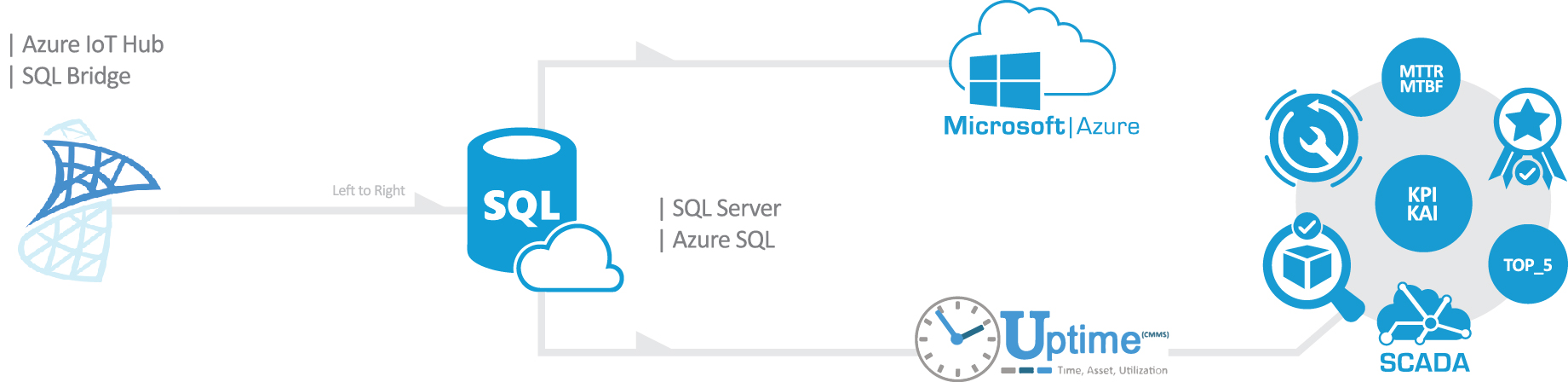

The IoT Solutions team knew that the market required a software solution that offers more than just a maintenance management system. Using our knowledge of the manufacturing environments, Our Solution evolved into an integrated Business Intelligent System (BIS). Our Solution integrates into any manufacturing environment, making use of existing hardware and software. If not available, cost effective hardware and software is installed to bridge the data transmission gap.

Our Solution offers a visual management system to instantly highlight problems detected, either by means of Visual Interfaces in the workplace, or via mobile applications. By using the ANDON industry standard, SCADA interfaces and Microsoft Power BI, Our Solution effectively offers a cost-effective visual management system to you. Our Solution are robust enough for any environment, as well as support all the functions within the workplace. Our solution is flexible enough to be tailored to any manufacturing environment and to meet unique customer demands.

Our Solution

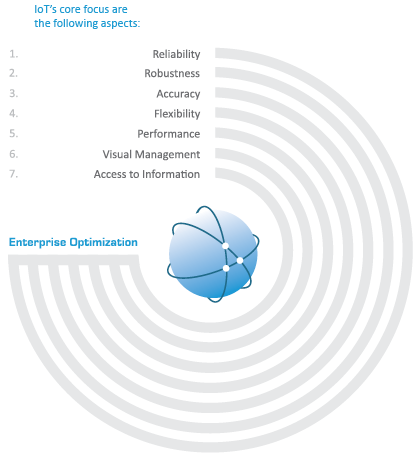

Our Solution has evolved into a fully integrated system that the team initially envisioned. It integrates all the aspects of the maintenance and manufacturing environment effortlessly. Our Solution offers more than the traditional BIS system, which is dependent on manual document inputs. The key is: We obtain our data at source! Our quality control and dynamic Statistical Process Control (SPC) module ensures that our customers have full control over their products, thus, the ‘software birth’ of IoT Solutions. Due to a big demand the team decided to focus on a single industry; Manufacturing. With the integration of our software on Microsoft products and Data Centre services, our IoT Solution facilitates any manufacturing platform.

We make use of multiple hardware loggers to integrate into the manufacturing environment where the use of OPC so ware packages are not available. This ensures the ability to integrate into nearly any manufacturing environment effortlessly. The IoT Solutions team implement and maintain to meet our customers’ standards. Our Solution has a fully integrated visual management system to SCADA, thereby putting our Solution ahead of the competition, as most other system requires the support of third party applications.

This system is used to display data on the production lines, on any mobile smart device and Azure Power BI. The system is built around the ANDON standard, but can be tailored to any customer standard or requirement. Our Solution offers our customers a robust management tool that enables them to effectively and successfully manage their manufacturing maintenance and quality environments. The system improves daily with the main focus of offering our customers a system that is: Reliable in-all Aspects, has Robust Adaptability, is 100% Accurate, Industry Flexible, Performance Guaranteed, and Visually measurable.

Capturing the Data

Converting the Data

Industries